Toyota Kata Contd..

leenaJanuary 29, 2014

One of the key learnings from Toyota Kata book is the importance of word Continuous in Continuous Improvement. When we say Continuous, it should be happening every day without fail. As mentioned by Chad Fowler in this post, improvement at small step has to happen everyday rather than once in a while. Thats what differs from Continuous Improvement from just Improvement.

As per the book, there are 3 ways which are perceived as Continuous Improvement i.e. Workshops , Value Stream and Action Item Lists. Those definitely help us to improve, but its never continuous. Lets see them in detail:

Workshops

Workshops are usually for a certain duration say a couple of days to a week. Usually learnings from the Workshops results in improvements, but its never Continuous. What I meant to say is that the learnings from the improvements cannot give us input for daily improvements and only daily improvements can be considered as Continuous Improvement.

Value Stream

Value stream is also known as optimising the lead time i.e. optimising the time taken from an idea to delivery. But the problem with this approach is that, it usually results in scattering the peace meal. Optimising Value Stream means optimising the different processes of delivery. So the usual struggle is whether to look at value stream as a whole or look at the individual processes beneath that. The first one will be too abstract while the latter has the danger of missing the big picture. I am still trying to understand this point better, so will come back to this later :)

Action Item Lists

This is the most common approach i.e managers coming up with list of improvements and the team working on it. According to the author, the problem with this approach is that the list grows bigger and becomes unmaintainable. Ideally the bigger list should be considered as good thing, because that shows us the areas of improvement, but usually it has the reverse effect i.e the list is perceived as lot of problems which results in a negative impact. Another problem with this approach is that rarely these improvements are considered separately from the daily activity and it misses the big picture of why the improvement is required. As discussed already, Continuous Improvement should be something that everyone should be doing everyday as part of their job without fail, rather than an activity done at a specific time of the day.

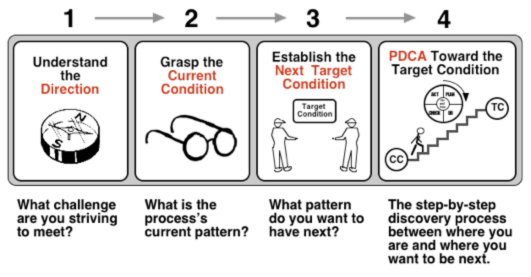

So the summary is continuous improvement is aligning two things i.e. target condition (where we want to be) and current condition (where we are now). Kata, the way of keeping two things in alignment or in synchronisation with one another, will help us to keep the current condition and target condition in alignment.

The following image should explain the Improvement Kata better.

Does that mean that we should stop having Workshops or Value Stream or Action Item Lists. Definitely Not. Because those help us improve, but relying on them for Continuous Improvement may not be a good idea.